The merits of having a mold built in the United States

JSC Enterprises has been in this business long enough to have worked with, or attempted to work with, molds that were created in Asia (more specifically, China). Many of these molds are not built to meet strict tolerances, since they don’t have to be. As labor costs rise in China, this no longer becomes an affordable manufacturing process. In addition, molds made in other countries are made from lesser quality steel or from aluminum. Again, this causes quality issues and shortens the life of the mold. Most high-production molders in this country use only the best steel available for the mold base and cavities. They utilize the latest technology in CNC machining and have seasoned tool makers who know how to create molds that meet the highest performance standards. When choosing your tool maker, be sure to look for U.S. based manufacturers.

Not all quotes are created equal

Procurement and purchasing managers have the unenviable task of obtaining quotes from a few mold makers for each project. Depending on the input (in terms of drawings, prototypes or sample parts), the cost quotes can vary greatly. Designers should look at all of these inputs and determine the best molding solution. They may redesign the part to maximize manufacturing efficiency and increase the number of parts that can be made with each molding cycle. Generally, molds made with tighter tolerances, more cavities and longer production life will take longer to build and will cost more upfront. The savings with a high-quality mold are long-term. These molds require less maintenance and last longer than lower quality molds.

Variables that impact the cost of a plastic injection mold

The core metal: For shorter production runs, some mold makers will use molds made from aluminum. This is a perfectly reasonable choice if you will not need the mold to perform long-term. However, if a project requires that a mold lasts for several years, an aluminum mold may cost more in the long-run.

The number of cavities: It is pretty intuitive when you think about it. Fewer cavities in a mold require less tooling work and time and ultimately less cost. A reputable experienced molder will be able to maximize cavitations in the mold to maintain the highest level of productivity. In general, most molders recommend creating one mold per part versus creating a family mold. Family molds are created with various cavities for assorted parts. They tend to produce inferior products and have more downtime due to maintenance issues.

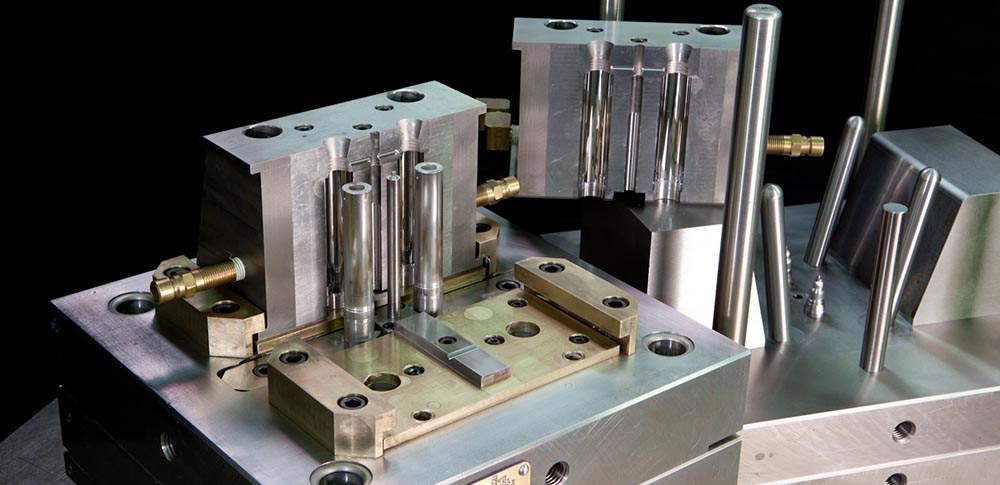

Mold base: Think of the mold base as a case that holds all of the mold cavities, inserts and components together. The cost of the base is estimated based on the size of the mold and the type of steel used to make the base as well as the customization required. Most mold bases come in standard sizes and are further machined to meet the requirements of a specific project.

Core/Cavity machining: All molds must also be customized. Customization includes the placement of cores, cavities, ejectors, cooling lines, etc. The steel used in the tool also impacts cost. Hardened steel molds lasts the longest and are more expensive to machine. Once done, however, they have a long production life.

Part complexity. Just as the number of cavities plays a role in determining the cost of the mold, so does part complexity. This includes the surface finish of the final part as well as the number of undercuts required. Parts, which demand tight tolerances, also contribute to the mold complexity.

Turnkey or vertically integrated injection molders

Some mold builders also manufacture the parts. This type of integration can help defray the mold building cost. Often full service molding manufacturers will subsidize a portion or all of the cost of the mold based on the full term and value of the manufacturing contract. They will amortize the cost of the mold so they can maintain profit margins while providing the lowest possible per piece cost to their clients.

The cost of a quality injection mold is certainly a major expense. However, tight-tolerance, precision molds that are made from the best steel available should last for years to come. The upfront cost must be calculated or amortized into the lifetime value of the project. Will these parts be in production for several years or several months? Does the project require a high-volume of parts? Are faster cycle times required? If you answered yes to these questions, then the initial investment in a quality mold will lower the per part cost and will end up saving money in the long-run.

We hope this overview of key cost factors helps you in getting and comparing quotes for your future projects. Working with a reputable on-shore molder, with a long-history of mold building for various industries, is a great place to start your bidding process.

Bablofil

7 years agoThanks, great article.